Engineered Air

Get Started

We will get back to you as soon as possible

Please try again later

What Does Engineered Air Do?

- Heating

- Air Conditioning

- Ventilation

- Refrigeration

- Energy Recovery

- Heat Transfer Products

Direct Fired

HE Series - Commercial - Industrial Direct Fired Heaters

The HE Series make-up air units offer the most efficient method available to heat make-up air. Direct fired make-up air heaters may be considered to be 100% efficient because no heat is vented to the atmosphere.

The theoretical 100% efficiency should be reduced to 92% due to water vapor being formed as a natural by-product of the combustion process. Units are available with heating capacities up to 14,000 MBH and air capacities up to 100,000 CFM. Units are also available in variable capacity, dual capacity, air curtain, and / or heat recovery configurations.

RE Series - Industrial Recirculating Direct - Fired Heaters

The RE Series mix air units offer the most efficient method available to heat mix air. Direct fired make up air heaters may be considered to be 100% efficient because no heat is vented to the atmosphere.

The theoretical 100% efficiency should be reduced to 92% due to water vapor being formed as a natural by-product of the combustion process. Units are available with heating capacities up to 11,000 MBH and air capacities up to 100,000 CFM. Units are also available in variable capacity, dual capacity, air curtain, and/or heat recovery configurations.

Indirect Fired

DJ Series Commercial - Industrial Indirect Fired Heaters

The DJ Series is divided into three models:

DJS SERIES

Our standard model DJS Series indirect fired heating operates with a nominal combustion efficiency of 81%.

DJE SERIES

The DJE Series indirect gas fired unit best matches our previous model series, also with the nominal combustion efficiency of 80%.

DJX SERIES

The most advanced model and highest combustion efficiency rating in the markeplace of 91% is the DJX Series indirect gas fired unit.

All DJ Series models feature high turndown burner, Stainless Steel two or three pass heat exchangers which offer longer heat exchanger life expectancy in cold climate operations with 100% outside air operation capability.

The DJ modes are available with heating capacities between 100 and 3,000 MBH. With the proven exclusive Engineered Air DJM Controller all DJ models are capable of 15:1 burner turn down ratios with a range of control options.

DG Series Commercial - Industrial Indirect Fired Heaters

The DG Series indirect fired heating units utilize our Engineered Air High Turndown Burner or optional purchased burner. Our Stainless Steel two pass heat exchanger offers long life expectancy and efficiencies as high as 82%.

The DG Series of industrial indirect fired heaters offers heating capacities between 1,400 and 7,500 MBH. When supplied with the Engineered Air G-TRAC control and our High Turndown Burner, the unit is capable of 20:1 turn down ratios.

Optionally the DG Series units can be configured for high discharge temperature industrial applications.

DGP/DJP Series Commercial - Industrial Air Turnover Systems

Space Temp Air Turnover Systems offer a solution to the universal problems of heating high bay areas: stratification, uneven temperature, and high energy costs. Other heating systems, most notably unit heaters and infrared heaters, tend to intensify stratification, and provide “spot” heating. These systems cannot provide a uniform space temperature and increase the amount of energy required to heat the space.

DJX Series Indirect Condensing Appliance

The Engineered Air DJX Series furnaces redefine heating for the commercial – industrial market place. Our complete line of indirect gas-fired heating products incorporates independent proportional control of combustion air and gas flow. This ability to maintain the proper ratio of combustion air to gas burned is called “linearization”.

With Linearization our DJX Series product maximizes heating efficiency and Energy Savings. DJ models meet or exceed the ASHRAE 90.1 2007 and ASHRAE 189.1 high performance building requirements for (non weatherized) steady state at high fire operation.

The DJX heat exchanger was engineered to operate at nominal 91% efficiency throughout its complete firing rate and with increased efficiency during part load conditions. The DJX Series exceeds standards and optimizes energy performance.

XE Series Indoor Fired Heating, Ventilating and Makeup Air Heaters XE Series High-Boy XE Series High-Boy

Standard Features

- Slide out burner / control assembly, and blower / motor assembly, for ease of servicing

- Washable hammock style filters

- Blowers with ball bearings

- Aluminized steel heat exchangers

- USA - Derate Natural Gas sea level inputs 4% for every 1000 ft. above sea level

- Canada - Derate Natural Gas sea level inputs by 10% to achieve high altitude ratings

RT Series Outdoor Heating Units

Standard Features

- Weatherproofed Casing - designed to withstand Canadian weather conditions

- Convenient Remove Start - electronic flame safeguard; reset accomplished at thermostat

- Aluminized Heat Exchangers

- Direct Spark Ignition - 19,000 volt synchronous direct spark ignition system eliminates pilot

- Powered Venting - constant draft regardless of outside weather conditions

- USA - Derate Natural Gas sea level inputs 4% for every 1000 ft. above sea level

- Canada - Derate Natural Gas sea level inputs by 10% to achieve high altitude ratings

Air Handling

LM / LMD Series Commercial - Industrial Air Handlers

Engineered Air's LM / LMD Series custom air handling units offer you the best of all worlds in designing your air handling system. Combined with our custom coil manufacturing abilities the LM / LMD Series can be configured with heating coils, cooling coils, evaporative cooling sections, return air mixing box, or even heat recovery packages.

The LM series units are designed with forward curved fans, backward inclined fans, airfoil fans, or plenum fans.

LMK Series Commercial - Industrial Electric Heaters

Engineered Air's LMK Series custom air handling units offer you the best of all worlds in designing your air handling system. Our LMK electric heat units incorporate our H-TRAC binary control for heat modulation.

By staging the heat supplied this control minimizes utility bills while ensuring that the buildings comfort requirements are met. Our air handlers are catalogued with air capacities between 750 CFM and 70,000 CFM - (Custom applications provided up to 150,000 CFM).

LMK Series Commercial - Industrial Electric Heaters

Engineered Air's LMK Series custom air handling units offer you the best of all worlds in designing your air handling system. Our LMK electric heat units incorporate our H-TRAC binary control for heat modulation.

By staging the heat supplied this control minimizes utility bills while ensuring that the buildings comfort requirements are met. Our air handlers are catalogued with air capacities between 750 CFM and 70,000 CFM - (Custom applications provided up to 150,000 CFM).

Air Conditioning

FWE Series Commercial & Industrial Mechanical Cooling / Heating Units

Our FWE Series of packaged air conditioners are completely custom designed to meet your needs, the units can be configured in cooling only or heat cool design. We offer a large assortment of both new and retrofit multi-zone designs. This product can also be integrated with our heat wheel or heat pipe products to minimize equipment loads and facilitate dehumidification.

Standard configuration for an FWE series product includes forward curved fans but can be modified to include Backward Inclined fans, Airfoil fans, Plenum fans, etc...

UPEW Series Water Cooled Packaged Air Conditioners

The UPEW Series of water-cooled packaged air conditioners provide a low cost, factory fabricated, cooling / air handling system requiring only a simple connection of the space thermostat and a supply of condenser water.

The UPEW Series lend themselves to small office buildings, commercial retail space and food service areas where the use of air-cooled equipment is not feasible. Water-cooled air conditioners provide significantly higher Energy Efficiency Ratios (EER).

FW/HE Series Mechanical Cooling / Direct Fired Makeup Air Units

The FW/HE series may be used to provide makeup air in commercial kitchens, cafeterias, and restaurants. In all cases, the exhaust air must be ± 10% of the makeup air, or as required by local codes.

FWE/HE units are available with side, up, or down discharge. Roof curbs are available where required.

FW/DJ Series Mechanical Cooling / Indirect Fired Makeup Air Units

A makeup air unit combining the economy of efficient indirect fired heating with mechanical cooling. The option blow through filter and evaporator coil eliminates nuisance trip outs due to frosting during the winter months.

FW/DJ units are available with side, up or down discharge. Roof curbs are available where required.

CU Series Air Cooled Condensing Units

Features

- Multiple staged compressors and / or modulating compressor

- Energy efficiency verified models available

- R-407C, R-410A and optional R-134a refrigerants

- Single circuited hermetic scroll compressors

- Tandem circuited hermetic scroll compressors available

- Your equipment solution for sustainable buildings

- 3 to 120 ton units

- Custom units for non-catalogued capacities

- Multiple independent compressor circuits

- Indoor and outdoor configurations

- Unit base fabricated from steel channel

FW/EC Series Packaged Air Conditioners with Evaporative Condensers

Engineered Air has developed the FW/EC Series of packaged air conditioners to meet the demands for lower air supply temperatures, in the 44°F - 50°F range, while meeting the operating efficiencies of ASHRAE Standard 90.1.

The FW/EC series of air conditioners utilizes the benefits of evaporative cooling in the condenser, allowing condensing temperatures in the range of 100°F to 110°F, even with ambient dry bulb temperatures at 100°F or over, as long as the web bulb temperature of the outside air is at 80°F or lower.

MZ Series Commercial - Industrial Heating and Cooling

Multizone Units for new or replacement applications designed to meet the needs of the 21st century.

REDUCED ENERGY CONSUMPTION THROUGH:

- up to 15:1 turndown with gas heat

- multiple compressors

- improved control systems

MC Series Commercial & Industrial Water or Air Cooled Modular Chillers

The Engineered Air MC Series is a line of modular water-cooled and remote air-cooled chillers (packaged air cooled are available) that range in size from 20 to 80 nominal tons. They can operate as a stand alone unit or in combination of up to 12 chiller modules to increase cooling capacity as needed. Single stand-alone models are available in the 3 to 80 ton range.

The principle of modular chiller design is that a smaller individual chiller (a module) can be connected with other modules to create a larger cooling system, either initially or over time. Sections of 6" (152mm) diameter pipe connected with Victaulic couplings are used to form a common header. This allows the common header to be pre-shipped to the job site and piped into the building piping system before the rest of the equipment arrives.

Humidity Control

PD Series Pool De-Humidifier

Engineered Air manufactures a variety of products that can be used for dehumidification.

Our PD Series of Pool Dehumidifier units cool, dehumidify and reheat air from pool areas. They can also incorporate heat recovery of the exhaust air for additional operating cost savings.

CD Series Ice Rink De-Humidifiers

Engineered Air manufactures a variety of products that can be used for dehumidification. Our CD Series of Ice Rink Dehumidifier units solve the condensation problems frequently encountered in skating and curling rinks.

SH Series Commercial - Industrial Gas Fired Steam Humidifier

Engineered Air is the proven leader in combustion and heat exchanger technologies. Our high turndown burner and floating, stress relieved heat exchanger have been quality tested for over 25 years of use involving thousands of installations.

Dedicated Engineered Air controls, specifically designed for EngA Burners, are used to achieve up to 15:1 fully modulating turndown ratio. The ability to modulate the combustion process, while maintaining or increasing the efficiency throughout the turn down range, results in the lowest energy cost per pound of steam produced.

This recognized combination of Engineered Air TRAC controller, burner and heat exchanger is further enhanced to achieve minimum capacity duration at high altitudes.

These proven technologies are the heart of the Engineered Air SH Gas Fired Humidifier.

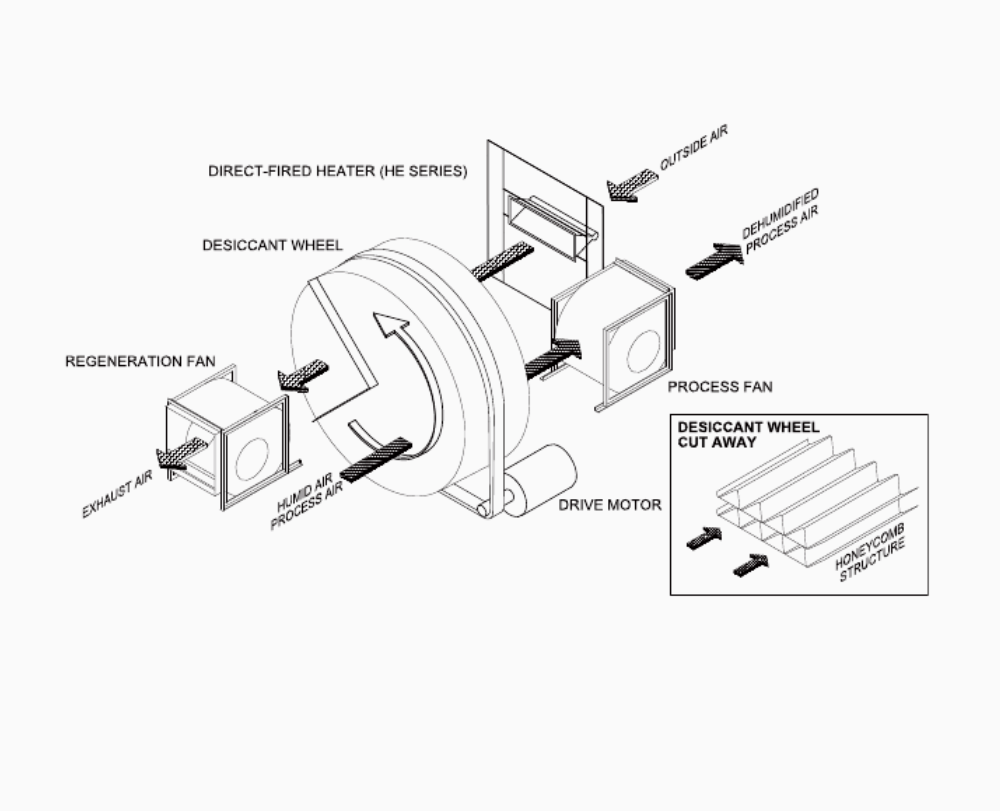

HE/DWD Series Gas Fired Desiccant De-humidification Unit

Engineered Air's HE / DWD Series of fully packaged process / industrial units are ideal for removing moisture in a variety of applications, even in low humidity conditions.

HE/DWD Series

HE/DWD Series

Gas Fired Desiccant Dehumidifier

Energy Recovery & IAQ

HRP Series Industrial Air to Air Thermal Recovery Units with QDT Heat Pipe

Engineered Air's HRP Series is an energy recovery package specifically designed to reduce the high cost of conditioning ventilation air by recovering a significant portion of the thermal energy from the exhaust air. This is accomplished with EngA's QDT Heat Pipe which has a nominal 60% recovery factor.

HRW Series Packaged Heat Recovery with EngA's Total Energy Wheel

Our custom manufacturing facilities allow us to incorporate HRW Heat Wheels into products such as Indirect-Fired Gas Heating and Mechanical Cooling equipment.

When providing 100% outside ventilation air the Total Energy Wheel can drastically reduce cooling loads, heating loads and help to control humidity problems in any building. Combined with our state of the art W-TRAC controller we help you maximize building efficiency in both summer and winter applications.

HRA Series Packaged Heat Recovery with EngA's TRP Air to Air Heat Exchanger

Engineered Air's HRA Series is an energy recovery package specifically designed to reduce the high costs of conditioning ventilation air by recovering a significant portion of the thermal energy from the exhaust air.

APPLICATION

Air to air heat exchangers can be employed in any ventilation system to reduce energy consumption. Systems that see the greatest benefit are the ones that have high volumes of hot exhaust air that also need to preheat cold outside air.

With options including auxiliary heating, cooling, flexibility in unit configurations, control systems and protective coatings, HRA units can be effectively used in many situations.

HRG Series Glycol Run Around Heat Reclaim System

A completely packaged system of HEAT RECLAIM including supply and exhaust blowers, heat transfer coils, filtration, supplemental heating, temperature controls and limits, and roof mounting frames.

Combined with proven Engineered Air heating systems to augment the reclaim system:

HE SeriesDirect Fired Burners

HE-K SeriesElectric Resistance Heaters

DG SeriesIndustrial Gas or Oil Burners

LM SeriesHydronic Heating

Utilize the Engineered Air computerized coil selection process to optimize the fluid handling system components for maximum efficiency and minimum cost.

UVC Series EngA's UV Centurion Lighting System

Engineered Air's UV-C Lighting System, UV-Centurion, uses the latest UV-C lighting technology to control surface mold and microbial growth on your Air Handling Unit's (AHU) cooling coil, drain pan and filter bank. Placement of the UV-Centurion within the AHU is critical to properly irradiate the surface pathogens. Use of this total lighting system ensures the absence of surface growth, providing reduced maintenance costs and continued maximum operational efficiency of the air handling unit.

UV-Centurion direct and indirect irradiation design provides proper UV-C ray dispersion to cover the total controlled surface, killing most common molds, bacteria and viruses in under 60 seconds.

SI Series Odor Removal for Commercial and Industrial Applications

The SI Series Oxidizer Units are self-contained air purification products designed to reduce high concentrations of odor & VOCs. They are a very economical solution, using minimal power consumption & requiring no additional chemicals or high priced media for operation and have extremely low maintenance.

The Oxidizer process is simple. High static voltage ionizes oxygen and then using basic principles of organic chemistry it naturally breaks down (oxidizes) gaseous compounds, leaving CO2, H2O and O2 as the primary end products.

For maximum results, the Oxidizer units should be connected to the suction side of any ducted system to maximize contact time between the oxidant and odorous gases.

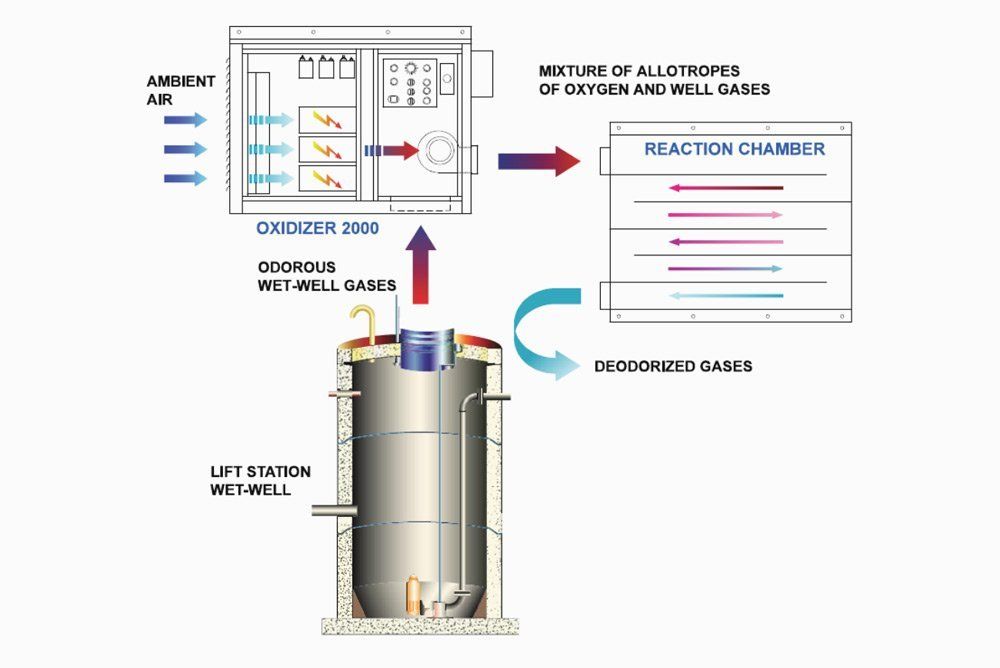

Oxidizer 2000 Odor Reduction System for Waste Water Applications

Oxidation technology can be effectively employed to break down odorous gases formed in wastewater facilities or any industrial site that causes problems for those living or working nearby. The oxidation process allows a form of oxygen (ozone) to combine with odorous molecules to break down the chemical structure and reform the atoms into simple compounds. Ozone is found naturally in the outdoors. Ozone is created by ultra violet rays from the sun or by high voltage electrical discharge during lightning storms. EngA’s Oxidizer 2000 copies nature by using high voltage to create a concentrated ozone discharge.

Heat Transfer

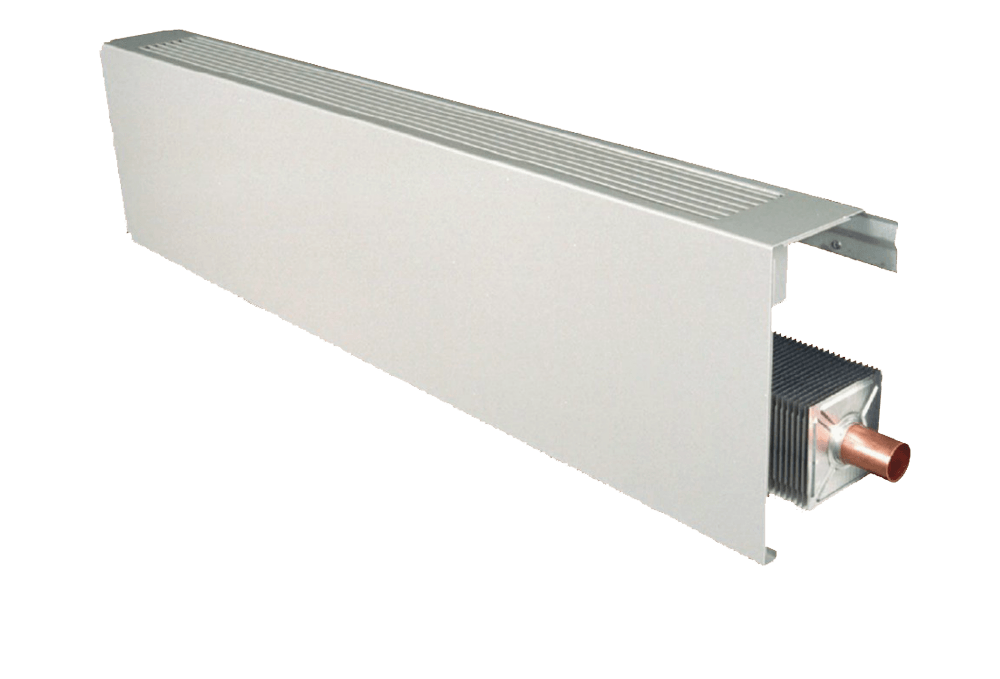

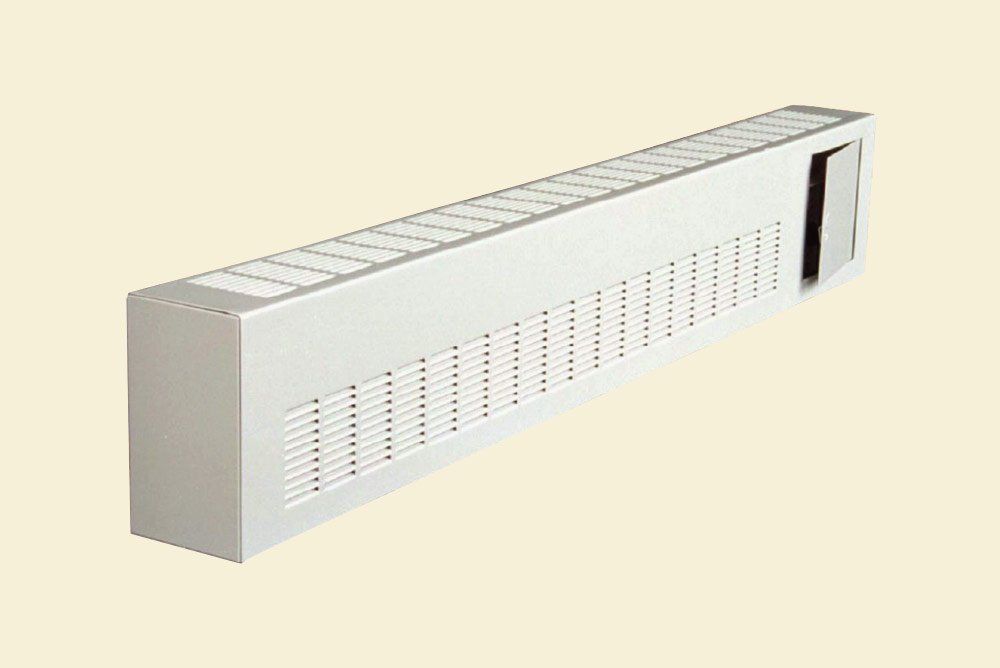

WF Series Finned Tube Radiation Solutions

Engineered Air offers an extensive line of hot water, chilled water and steam heating products for commercial, industrial and institutional application. As with all Engineered Air products our Heat Transfer Products can be customized to meet your specific needs.

Engineered Air offers either copper or steel tube element to meet you finned tube radiation requirements. Our Galvanneal steel enclosure is treated with a multi-step Oakite Cryscoat preparation before being electrostatically painted with an epoxy powder coat prime finish. You then can choose from a variety of colours at minimal additional cost for your custom baked enamel finish coat. We offer a wide variety of enclosure styles as well as custom designed enclosure.

Profile Series Finned Tube Radiation Solutions

The Engineered Air Profiles Series enclosure is produced in heights of either 8” (203mm) or 10” (254mm). The Profile Series enclosure is available in lengths from 2’-0” (610mm) to 7’ - 6” (2286mm) in 6” (152mm) increments.

In addition to Profile Series enclosures, Engineered Air can provide, upon request, custom designed models in a size, metal type, gauge and paint finish to suit any desired application.

C Series Convector Radiators

CUH Series Cabinet Unit Heaters

H Series Horizontal Unit Heaters

Engineered Air manufactures the complete line of Horizontal and Vertical Unit Heaters with the following options: minimum 18 gauge (1.3mm) 304 Stainless Steel with Heresite coated coils and Totally Enclosed motors. The Stainless Steel Unit Heater is more than just great looks!

V Series Vertical Unit Heaters

Engineered Air manufactures the complete line of Horizontal and Vertical Unit Heaters with the following options: minimum 18 gauge (1.3mm) 304 Stainless Steel with Heresite coated coils and Totally Enclosed motors. The Stainless Steel Unit Heater is more than just great looks!

EngFlo Series Forced Convection Radiators

Engineered Air EngFlo forced convection finned tube radiation features high capacity in a small profile. Quality aluminum tangential blowers provide forced convection for those high heat loss areas.

Engineered Air's rugged 16 gauge (1.5mm) construction is standard in our two units, EF-50, 50" (1270mm) and EF-100, 100" (2540mm). The EF-100 consists of (2) 50" (1270mm) covers and (1) 100" (2540mm) base unit.

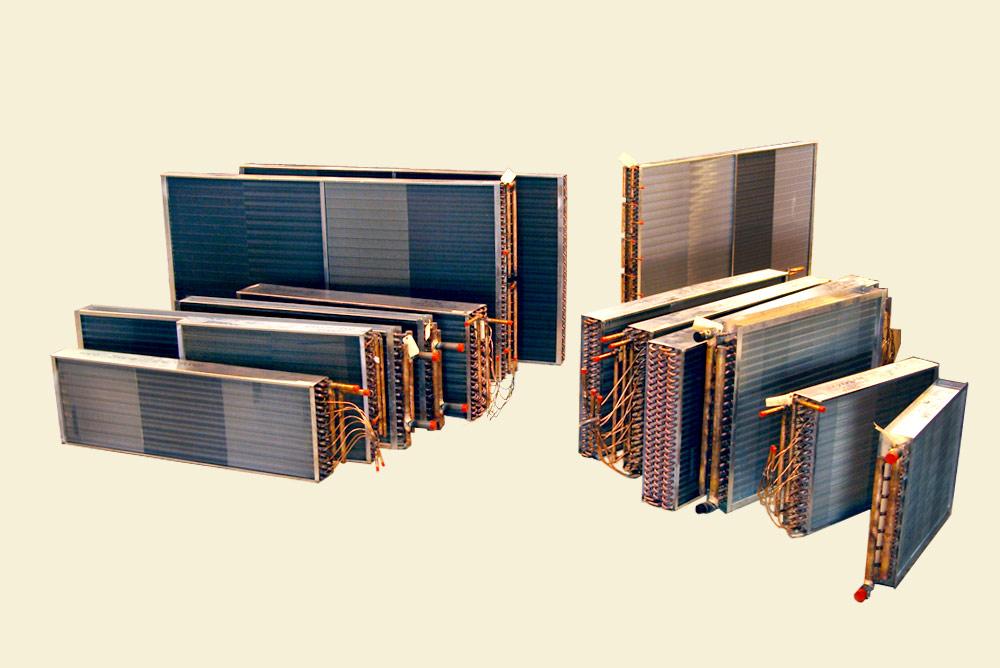

Heat Transfer Coils Commercial & Industrial Heating / Cooling Coils

Engineered Air high performance heat transfer coils have found wide acceptance in heating, cooling, dehumidification and heat reclaim applications, ranging from schools, churches, hospitals and high rise buildings to gas plants and manufacturing facilities. Engineered Air heat reclaim coils utilizing glycol or refrigerant provide substantial savings each year to owners of computer rooms, supermarkets, industrial process plants and other applications.

UV Series Commercial & Institutional Unit Ventilator

Unit Ventilators are made by the Heat Transfer Division of Engineered Air in four basic models, all in either draw through or blow through coil configurations. The 4 models are traditional vertical, horizontal ceiling, single fan horizontal ceiling and floor to ceiling riser style. All models are available with self-contained DX cooling and/or Heat Recovery options.

RUVG Series Institutional & Commercial Gas Fired Unit Ventilators

- Riser Style Unit Ventilator

- HIgh efficiency indirect fired heat exchanger

- Two stage heating control or modulating (optional)

- ETL Certified (Canada and USA)

HERESITE for Finned Tube Heating, Cooling and QDT Heat Recovery Coils

The first HERESITE coating application to the exterior surfaces of finned tube coils took place in the early 1950s. Since that time the HERESITE baking phenolic coating has effectively demonstrated its value in protecting heat transfer coils from corrosive attack, thereby appreciably increasing equipment service life.

LAMIFLO Series Integral Face & Bypass Coils

Heating cold outside air with steam or a hot fluid is a risky business at the best of times; there is always a potential for a freezeup! But with steam of hot water, there is nothing better than Engineered Air's LAMIFLO Integral Face and Bypass Heating Coils. In the more Northern climates, with a significant number of hours per year under 32°F (0°C) outdoor air temperature, Engineered Air does recommend the use of glycol solution instead of hot water, particularly in areas where power failures are prevalent.

AIRTEX Radiant Ceiling Systems - The New Standard in Perimeter Heating

The Airtex extruded aluminum panels in lengths up to 16' (4877mm) have changed the way North America heats its buildings. Clean durable Airtex Radiant Linear products are great for the hospital, school, laboratory and office.

A continuous architectural perimeter band constructed to virtually any panel width from interlocking extrusions.

An innovative mechanical bonding technique maximizes heat transfer between copper circulating coils and aluminum extrusions.

AF Series Air Cooled Condensers

The AF Series Condenser is constructed of heavy gauge galvanized metal selected for long life in outdoor environments.

The Condenser coil is of copper tube / aluminum fin construction as standard although other materials are available as an option. Custom circuiting is utilized to provide optimum capacity with minimum pressure drop.

Proven components, which have withstood the rigorous test of time, are used in the air moving assemblies. Venturi openings are spun to exacting tolerance to insure maximum airflow with minimum horsepower requirements.

All electrical components (standard or optional) are of the highest quality.

Fan Coil Units Direct Drive and Belt Drive

Direct Drive Fan Coil Units (Blow Through) are available in three different models:

- HFC - Horizontal

- VFC - Vertical

- LFC - Lowboy

Belt Drive Fan Coil Units (Draw and Blow Through) are available in three different models:

- JM - Horizontal

- JMV - Vertical

- MT - Horizontal

Controls

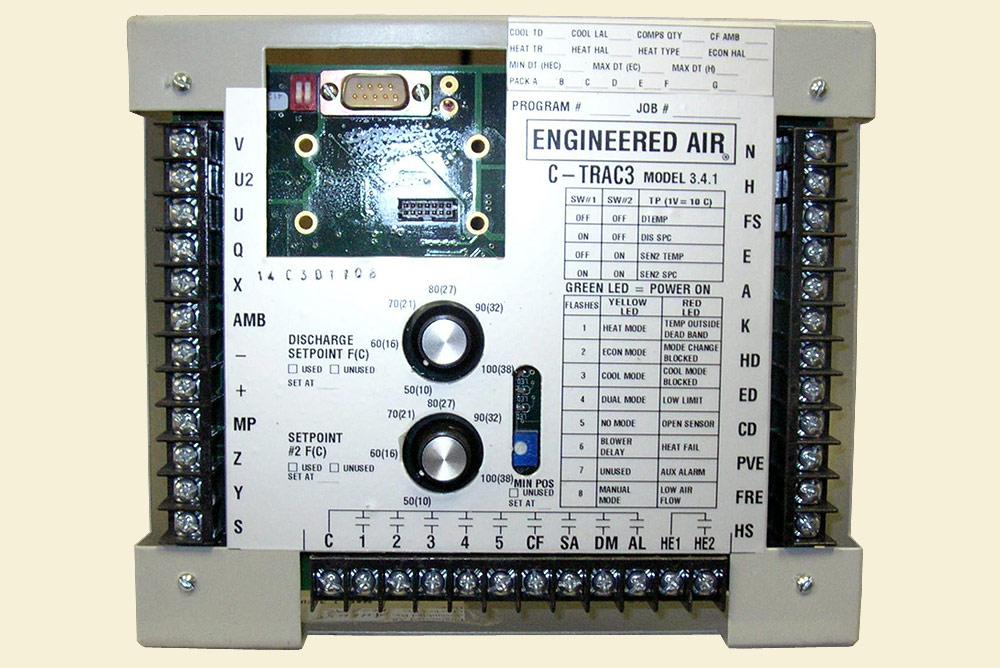

C-TRAC Cooling Sequencer

The C-TRAC Cooling Sequencer is a fully integrated Heating-Cooling control with Economizer, intended for use with packaged Direct Expansion cooling units, packaged air handlers with remote condensing units, or air handlers with chilled water and hot water coils.

It is the highest level of the TRAC Family. Other Engineered Air TRAC controllers can be slaved to the C-TRAC. The slaved heating controller receives a 0-10VDC control signal from the C-TRAC.

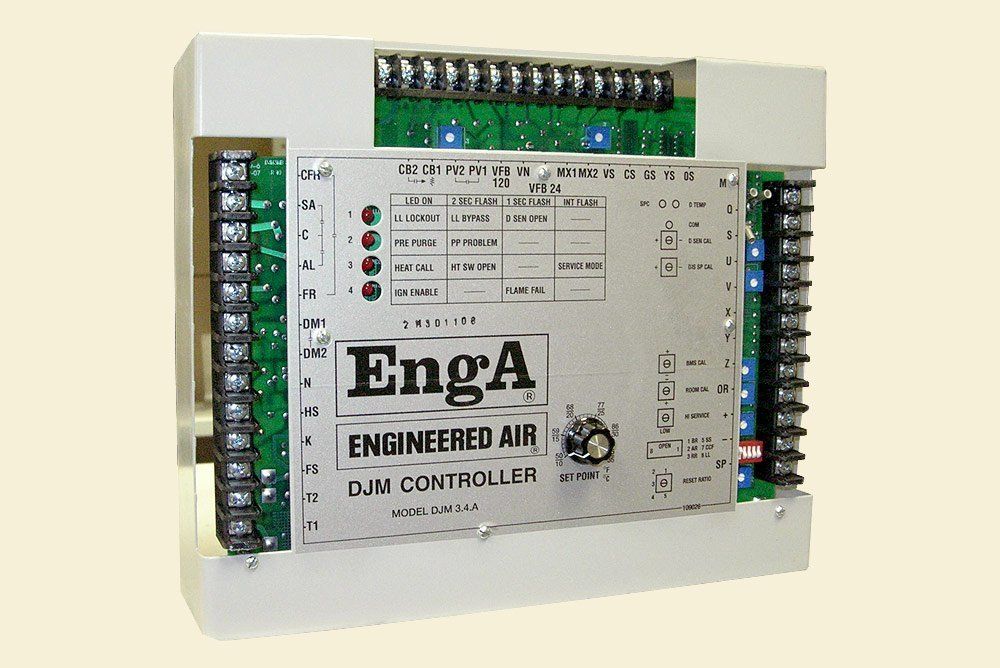

DJM Controller

The Engineered Air DJ Series indirect fired burners offer superior turndown and modulates both gas firing rate and combustion air quantity.

The DJM controller is a programmed logic device that provides proportional-integral control when used with any one of the DJ series burners. The basic function of the DJM is to control discharge air temperature. The discharge air setpoint can be set either at a fixed value, or can be reset from a number of options.

The DJM in its various forms can operate as either a stand-alone controller, or it can be interfaced with our C-TRAC mechanical cooling controller.

G-TRAC Industrial Gas Heater Controller

The G-TRAC Industrial Furnace controller has been designed to provide accurate proportional-integral control for indirect-fired burners with particular emphasis on allowing the burner to turn down to its full capability while maintaining acceptable flue-gas properties. The G-TRAC is unique among industrial gas-fired air heater controllers, in that the air-gas ratio is monitored throughout the entire turndown range, which, in the Engineered Air DG Industrial Heater, spans from full fire to 5% of full fire, or a turndown of 20:1.

Together the DG high turndown burner and the G-TRAC controller provide optimum air heater performance.

The G-TRAC is a stand-alone controller for the Engineered Air series DG Industrial Furnance. Alternatively it can be slaved from the C-TRAC Cooling Sequencer for integrated control of a packaged air conditioner, such as the Engineered Air FW-DG, or a split system using a DG heat section and a CU condensing unit.

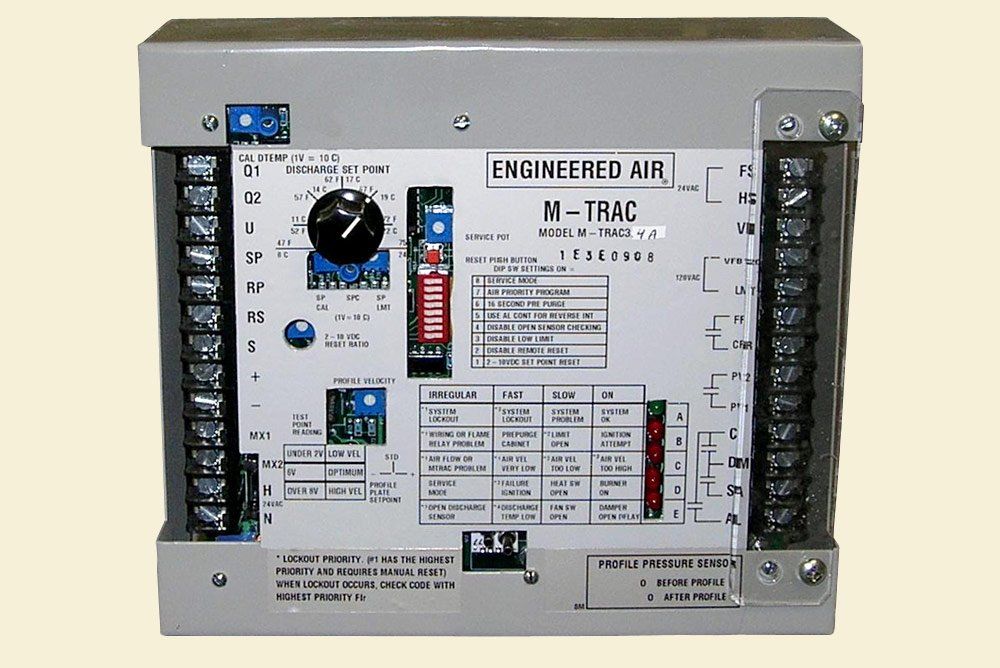

M-TRAC 1, 2, 3 Controller

The Engineered Air M-TRAC controller is designed to control Engineered Air HE Series direct fired burner on make up air units. M-TRAC controller is a programmed logic device that provides a stable PI (proportional + integral) temperature control and airflow monitoring system. A dual sensor option is built in the M-TRAC controller to provide an even discharge temperature.

The M-TRAC controller has eliminated many mechanical parts such as air proving switch, damper end switch, timers and relays. The M-TRAC provides interlock between the exhaust fan and the make up air unit. This allows the M-TRAC to prove the operation of both the exhaust fan and supply fan. Reverse interlock is also available. This feature is designed for use in buildings which should not go into a negative pressure condition during start up mode.

The Engineered Air M-TRAC controller is designed to be user friendly. The controller is equipped with five diagnostic LED lights. System status can be determined by the LED color and its flashing patterns. This features allows easier troubleshooting.

The M-TRAC in its various forms can operate as either a stand-alone controller, or it can be interfaced to a higher level controller such as a C-TRAC or programmable controller. When used as a stand-alone device the controller provides most of the control requirements of a make up air unit. Standard abilities include: discharge temperature control, supply blower control, burner management, inlet damper control, auto bypass low limit, and air flow monitoring.

X-TRAC Controller

Engineered Air X-TRAC is a logic controller designed to control XE, RT, PACK and DJ(E)-20&40 with constant combustion air. The X-TRAC was designed to replace the Maxitrol controller, provide excellent temperature control, increase control flexibility, and provide safety features as provided by other TRAC controllers used for gas heat.

The X-TRAC through the use of digital electronics, has eliminated many of the traditional control components resulting in fewer parts, simplified wiring diagrams and reduced wiring. The X-TRAC replaces the Maxitrol Series 21 amplifier & auto bypass low limit.

The X-TRAC uses a control scheme incorporating Proportional and Integral control (PI) to maintain discharge temperature at set point.

The X-TRAC was designed to be easily applied to the following control applications:

Discharge control with internal or remote setpoint

Two level room control. When room thermostat closes, discharge temperature is reset upward to a second discharge set point

Discharge control c/w external 4-20MA or 0-10VDC reset from BMS. Reset amount ranges from 5°F to 50°F

X-TRAC has built in non-recycling auto bypass low limit. It also has a self-check feature that ensures that the discharge sensor is operating within its tolerances. Two built-in status lights for heat call & lock out are provided.

H-TRAC Heat Sequencer

The H-TRAC controller has been designed to control staged electric heat applications. It utilizes a proportional-integral control stategy to sequence five binary style output stages.

The electric heat coil controlled by an H-TRAC controller is specifically designed with stages sized for operation with the binary control logic. Stage one is smallest, stage two is double stage one, and stages three, four and five are each four times the output of stage one. In this manner by activating various combinations of the physical stages, fifteen "equivalent" control stages are created (7 or 11 equivalent stages can also be provided.)

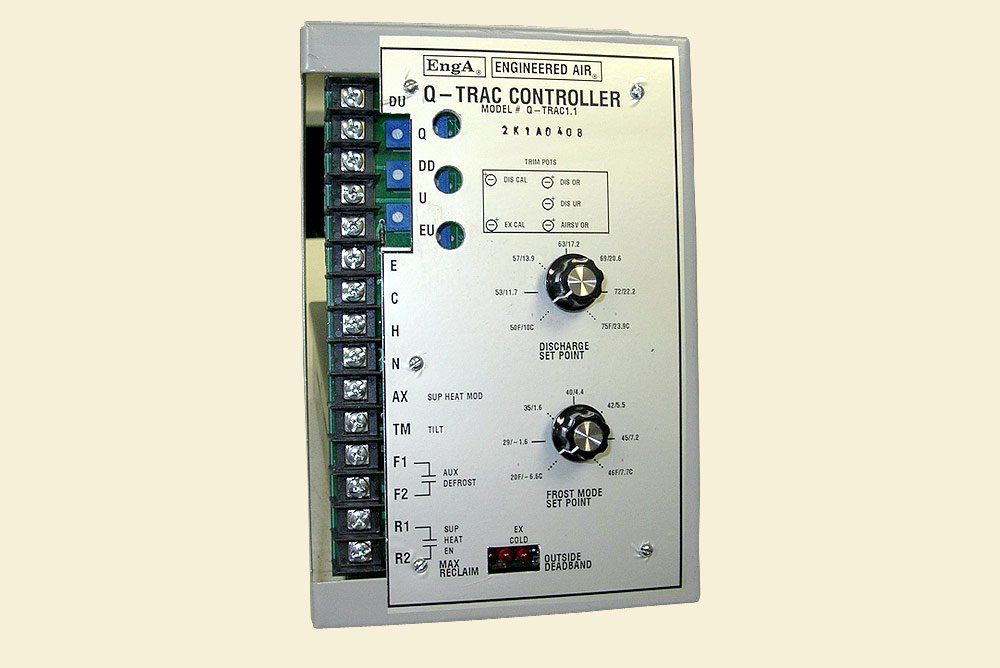

Q-TRAC QDT Heat Pipe Controller

The rate of heat transfer in a QDT heat pipe is dependent not only on the size, number of rows and fins, but also on the mounting angle. The Q-TRAC controller is designed to operate the tilt mechanism on a QDT heat pipe to control tilt angle.

Controlling the rate of heat transfer via tilt angle of the heat pipe has three objectives.

- Temperature control: supply air temperature leaving the heat pipe.

- Frost Prevention: maximizing heat transfer while preventing the formation of frost on the exhaust leaving side of the coil.

- Heating-Cooling changeover: by reversing the tilt angle, the direction of heat transfer is also reversed to allow summer operation.

The Q-TRAC control is a stand alone solid state device that provides proportional-integral control for all three functions when mounted on a QDT heat pipe with tilt mechanism.

W-TRAC Heat Wheel Controller

The rate of heat transfer in an Engineered Air heat wheel is dependent on the rotation speed of the heat wheel.

The W-TRAC controller is designed to provide variable speed control for an Engineered Air heat wheel. By controlling the rotational speed of the head wheel, and in turn controlling the rate of heat transfer, three functions can be accomplished.

- Control of supply air temperature leaving the head wheel.

- Prevention of frost formation on the exhaust side of the wheel while keeping heat transfer at the maximum allowable level.

- Heating-Cooling changeover. In heating mode heat is carried from the warm exhaust to the cold outside air. In cooling mode heat transfers from the warm outside air to the cooler exhaust air. The wheel simply rotates in either case and as such there is no difference in operation between heating and cooling. By stopping the wheel completely a free cooling mode can be provided. This is desirable if cooling is required and outside air is colder than the exhaust air.

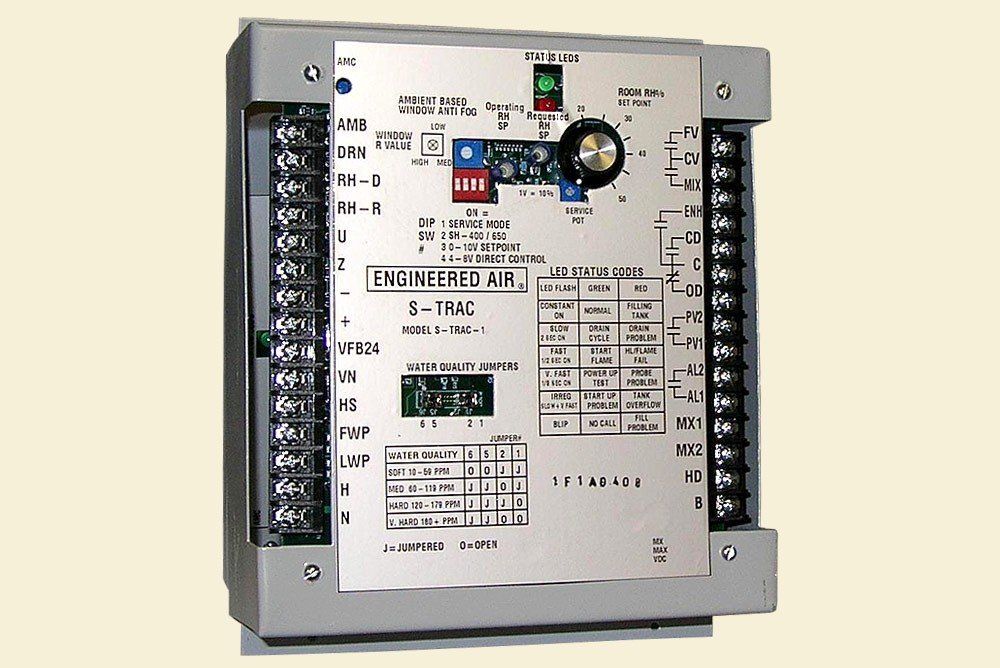

S-TRAC Humidifier Controller

The S-TRAC controller has been designed to control Engineered Air SH Series of gas fired humidifiers. It utilizes a proportional-integral control strategy to modulate humidity level.

The Engineered Air S-TRAC controller is a programmed logic controller. It has eliminated many mechanical parts such as timers, relays and water level controller. The S-TRAC provides water level, burner, humidity and system status control. It also has a built in drain cycle timer. The S-TRAC controlled SH humidifier will initiate a drain cycle depending on the hardness of the water and the firing rates of the burner. A mixing valve is also incorporated in the S-TRAC to eliminate high drain temperature.

The S-TRAC can be used in a variety of control applications.

- Room humidity control c/w S-TRAC built-in setpoint

- Room humidity control c/w BMS 0-10VDC setpoint

- Return air humidity control c/w S-TRAC built in setpoint

- Return air humidity control c/w BMS 01-10VDC setpoint

- BMS 4-8VDC direct control

- Ambient reset (to prevent unwanted condensation forming on windows and walls)

- Duct high humidity limit

Cleanroom Systems

Flush Ceiling Grid Systems

Engineered Air's Flush Grid System provides a variety of options from our standard welded bottom load, top load and stainless steel grids to our economical stick-built ceiling grid systems. Our vast array of Flush Ceiling Grids can be supplied with integral lighting and sprinklers to provide flexibility for your cleanroom needs.

Cleanroom Plenum Systems

Engineered Air's Cleanroom Plenum System provides custom modules manufactured to facilitate ease of installation and the ability to fit into a confined ceiling space. These modules can be supplied with plenum fans, coils, integral LED lighting and sprinklers, as well as a variety of controls.

Operating Suites

Operating Suites in today's market demand a lot of interface with the ceiling system. Engineered Air offers the perfect solution to customize the plenums with structural steel that allow the medical equipment to hang from, including boom mounts and rails. Our Flush Ceiling Grid allows for integration of LED lighting above the patient while allowing filtered air to be balanced precisely, at the desired velocity, to wash over the operating table.

Get a Quote

We will get back to you as soon as possible

Please try again later

-

Regina, thinking about Central Air Conditioning for your home 🏡? Spring has sprung ☀️, reach out to us today! ☎️: (306)-737-3405 📧: chriss@pro-west.ca 🖥️: www.pro-west.ca Your Local SaskEnergy Network Member.Button

-

Thinking about Central Air Conditioning for your home 🏡? Spring is already here ☀️ , reach out to us today! ☎️: (780)-513-2511 📧: danick@pro-west.ca 🖥️: www.pro-west.caButton

-

✨Day 3✨ of the @reginaspringhomeshow! Join us for the LAST DAY open now till 5 PM. Visit our booth at Aisle E, Booth 490 and say hello to Danick, Chris, Zach & Risa!Button

-

✨Day 2 at the @reginaspringhomeshow! 🔹Open from 10 am to 8 pm today. 🔹Come by and visit our booth at Aisle E, Booth 490 to enter our giveaway for 2 season tickets to the @sskroughriders 🏈!Button

-

Start a new career in a growing industry; Pro-West is hiring! Pro-West is continously expanding and we are looking for you to help us grow 🙋🏻♂️. Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📦 We are Western Canada’s largest supplier of Eberspaecher/Espar and Bergstrom products. 📍With several branches across Western Canada, there is plenty of room for growth, so why not start your future at Pro-West? Apply via our Careers Page! 🔗: www.pro-west.ca/careersButton

-

When it comes to mobile climate solutions in Western Canada, Pro-West is the name you can rely on. As an authorized Autoclima dealer, we offer on-site installations and repairs available 24/7, specializing in providing mobile climate solutions that ensure comfort, efficiency, and convenience. In conjunction with The Government of Canada’s: Green Freight Program, let us help your fleets reduce their fuel consumption and greenhouse gas emissions through fleet retrofits and logistical best-practice implementation. ➡️Auxiliary Power Units Retrofits: 50% up to a max of $10,000 per device for an electric APU ➡️With Fresco 9000, enjoy savings of up to $1500/month* *Assumes monthly idle time of 250 hrs Reach out to us today and have our team of skilled technicians provide you with comfortable, efficient, and convenient climate control solutions; keep your business operations running smoothly in any situation.Button

-

Regina, we’ll be at the @reginaspringhomeshow March 22nd-24th, 2024! Visit our booth in Aisle E, Booth 490! Explore an exciting promotion and stay updated on the recent advancements in cooling and indoor air quality. Learn about opportunities tied to the Canada Greener Homes Grant, designed to assist Canadians in enhancing the energy efficiency and comfort of their homes through eligible retrofits. Stop by, say hello, and learn more about renowned brands like YORK Home Comfort and TEMPSHIFT.Button

-

Please note our offices will be closed Monday, February 19th, to spend some much needed time with our loved ones. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511.Button

-

Regina, thinking about Central Air Conditioning for your home 🏡? Don’t wait till the warm weather arrives ☀️, reach out to us today! ☎️: (306)-737-3405 📧: chriss@pro-west.ca 🖥️: www.pro-west.caButton

-

Thinking about Central Air Conditioning for your home 🏡? Don’t wait till the warm weather hits, reach out to us today! ☎️: (780)-513-2511 📧: danick@pro-west.ca 🖥️: www.pro-west.caButton

-

Regina, keep warm and cozy with Pro-West ❄️! Furnace installations starting at $2,995! Reach out today for you no-obligation quote. ☎️:(306)-737-3405 📧: chriss@pro-west.caButton

-

Stay warm from the blistering cold with Pro-West 🥶! Furnace installations starting at $2,995. ☎️: Call us today for your no-obligation quote!Button

-

Best wishes to everyone; for health and happiness throughout the coming year! Please note our offices will be closed today, January 1st, to spend some time with our loved ones. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. 🎊 Happy New Year!Button

-

On behalf of the Pro-West team, Merry Christmas! Please note our offices will be closed December 25th and 26th respectively, to spend some much needed time with our loved ones🎄. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. Happy Holidays ❄️!Button

-

Please note our office holiday hours above for when we will be closed, to spend some much needed time with our families 🎄. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. Happy Holidays Everyone!Button

-

Grande Prairie 📣, we have furnace installations starting at $2,995! While the weather may be unpredictable, Pro-West is your reliable choice to ensure you & your family’s comfort 🙋🏻♂️! Contact us today to receive a free, no-obligation quote. ☎️: (780)-513-2511 📧: reception1@pro-west.ca 💻: www.pro-west.caButton

-

Get the best Furnace prices in town, with Pro-West! Price Match Guarantee 🙋🏻♂️. Reach out to us today for your free no obligation quote! ☎️: 306-737-3405 💻: www.pro-west.ca Your Local SaskEnergy Network Member.Button

-

Start a new career in a growing industry; Pro-West is hiring! Pro-West is continously expanding and we are looking for you to help us grow 🙋🏻♂️. Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📦 We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. 📍With several branches across Western Canada, there is plenty of room for growth, so why not start your future at Pro-West? 💻 Apply via our Careers Page!Button

-

Lest we Forget. To honour and express our deepest gratitude, our offices will be closed on November 13th and reopen at 8 am on November 14th. *Our on-call will be available for any emergency related-assistance you may require at 1-866-513-2511.Button

-

Winnipeg, the snows out 🥶! Stay warm this season with Pro-West 🙋🏻♂️. For just $99, schedule a furnace tune-up and receive a free filter with our service. Contact us today, to learn more about our top-notch residential services 🏡. ☎️: (204) 997-8131 💻: brentd@pro-west.caButton

-

Reach out to us today about this incredible offer! Get a 10-year Extended Labour Warranty on all YORK furnace-only plans for installations from now through December 31, 2023. Get the best furnace prices in town with Pro-West! Reach out to us today for your free no obligation quote! ☎️: 780-513-2511 💻: www.pro-west.caButton

-

❄️ Winter is here! Get the best Furnace prices in town, with Pro-West! Price Match Guarantee 🙋🏻♂️. Reach out to us today for your free no obligation quote! ☎️: 780-513-2511 💻: www.pro-west.caButton

-

📍 Winnipeg, explore our exceptional residential services and offers we have for you! While the weather may be unpredictable, Pro-West is your reliable choice to ensure your comfort 🙋🏻♂️! Contact us today to receive a free, no-obligation quote. ☎️: (204) 997-8131Button

-

Regina, it's time to get your equipment ready for the winter season ❄️! At Pro-West, we take pride in implementing top-notch solutions for heavy duty equipment 🛻. Our skilled technicians 🙋🏻♂️are here to guarantee your cabin or sleeping quarters remain warm and comfortable, all while improving cost-effectiveness and minimizing emissions through our anti-idling options. Our proficiency goes beyond anti-idling solutions where we offer comprehensive expertise in heating, across the 🚛automotive trucking industry and off-highway heavy equipment🚜. We proudly excel in servicing and repairing both stock and aftermarket heating components. Whether you need a new installation, service for maintenance, or a replacement part, reach out to Pro-West today! ☎️: 1-306-737-3405Button

-

While the weather might have its surprises, you can count Pro-West to make you comfortable! Reach out to us today for your no obligation quote 🙋🏻♂️. ☎️: 780-513-2511Button

-

Happy National Trucking Week! Thank you to all the drivers who traverse the nation's highways on behalf of us; spending long hours on the road and away from their loved ones, to make our lives easier and supply chains stronger. We're proud to be able to help make your journey comfortable with our Heavy Equipment services & installs.Button

-

Please note our offices will be closed today to spend some time with our loved ones; reopening tomorrow. 🙋🏻♂️Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. #HVAC #Prowest #WesternCanadaButton

-

Get ready for a scorching weekend ahead ☀️! Keep your cool with Pro-West, as we bring you the best ways to beat the heat. Our team of skilled technicians ensures not only a comfortable atmosphere but a top-notch service experience. Stay cool, stay comfortable – all with Pro-West! Call us today for your free, no obligation quote. ☎️ 780-513-2511Button

-

Regina! Enjoy this special offer for a central air conditioning system install; while quantities last 📢! ☎️ Call Pro-West today 🙋🏻♂️ 306-737-3405 #YorkAC #ProWest #ProWestRefrigeration #WesternCanada #Regina #HeatingandCooling #HVAC #HVACTechnicians #StayCool #AC #AirConditioner #Promo #Summer #CallNow #YorkHomeComfortButton

-

Espar Training with Pro-West! 🗓 September 19th, 2023 📍 Holiday Inn-2520 Portage Ave, Winnipeg, MB R3J 3T6 ⏰ 8:00am-4:30pm Take this fantastic opportunity to get certified with Espar, in just 1 day! 🚨 Space is limited 📧 EMAIL to register today 📧! #Eberspächer #Espar #Eberspacher #Espar #Eberspaecher #HVAC #HVACTechnicians #RegisterToday #Certified #Training #Airtronic #HeatingandCoolingButton

-

Please note our offices will be closed August 7th to spend some time with our loved ones. 🙋🏻♂️Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. #HVAC #Prowest #WesternCanadaButton

-

📣 Massive Overstock Clearance! ✨ 20% off on AC installations; while supplies last! 🔹Free Estimates 🔹No Payments, No Interest for 12 Months OAC 📞 Call Today: 780-513-2511 🔗 in Bio to our Website #Summer #ProWest #HVAC #YorkAC #WesternCanada #Residential #HeatingandCooling #HVACTechnicians #AC #AirConditioning #Install #CallToday #YorkHomeComfort #GrandePrairieButton

-

Are you familiar with CleanBC Heavy-duty Vehicle Efficiency Program 🛻 ? We are the heating and cooling specialists in Western Canada, providing installation and maintenance services for HVAC systems. One facet of our specialties in Langley, BC lies in installing and maintaining anti-idling technology for heavy-duty vehicles and trailers. We offer eco-friendly solutions to improve the efficiency of your mobile fleets! As authorized dealers of top-notch brands like Eberspacher Espar Kalori and Autoclima, we ensure high-quality products from industry leaders and exemplary service from our qualified technicians. Reach out to our 📍 Langley branch today! ☎️ 604-881-9108 🔗 in Bio to our Website #Langley #YVR #Vancouver #HVAC #AutoClima # CleanBC Heavy-duty Vehicle Efficiency ProgramEspar #Eberspacher #AntiIdling #EfficientTruckingProgram #Callus #HVAC #HVACTechsButton

-

Wishing everyone Happy Canada Day 🇨🇦! Please note our offices will be closed Monday, July 3rd to spend with our families; reopening Tuesday, July 4th. Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. #ProWest #CanadaDay #LongWeekend #WesternCanada #HVAC #HVACTechnicians #HeatingandCoolingButton

-

Massive Overstock 📣 Call today for this great deal for July installs! ☎️ : 780-513-2511 🔗 in Bio to our Website #ProWest #HVAC #YorkAC #WesternCanada #Residential #HeatingandCooling #HVACTechnicians #theExperts #Install #CallToday #YorkHomeComfort #GrandePrairieButton

-

Our AC installation services are available in Dawson Creek, BC 📍 ! Experience the assurance of quality with York and our dedicated installation team. Call us today to receive a complimentary, no obligation quote! ☎️ : 1-866-513-2511 #YorkHomeComfort #AC #Summer #HVAC #HVACTechnician #HeatingandCooling #ProWest #YorkAC #WesternCanada #CallNow #DawsonCreek #BC #CalltodayButton

-

Are you familiar with Manitoba’s 🛻 Efficient Trucking Program? We are the heating and cooling specialists in Western Canada, providing installation and maintenance services for HVAC systems. One facet of our specialties in Winnipeg lies in installing and maintaining anti-idling technology for heavy-duty vehicles and trailers. We offer eco-friendly solutions to improve the efficiency of your mobile fleets! As authorized dealers of top-notch brands like Eberspacher Espar Kalori and Autoclima, we ensure high-quality products from industry leaders and exemplary service from our qualified technicians. Reach out to our 📍 Winnipeg branch today! ☎️ 204-885-0324 🔗 in Bio to our Website #Winnipeg #Manitoba #HVAC #AutoClima #Espar #Eberspacher #AntiIdling #EfficientTruckingProgram #Callus #HVAC #HVACTechsButton

-

Experience the confidence of over 125 successful AC installations this year alone! Don't just take our word for it, see what our satisfied customers have to say below. When it comes to heating and cooling in Grande Prairie, we're the specialists you can trust. 🔹“From the beginning these guys treated us like gold. Quick to answer any and all questions, was honest about the work that was needed and the price estimates. Friendly, professional and easy going employees. The guys who came to do the work in our house were respectiful and clean. Great experience all around and would highly recommend 👌🏻” 🔹“Absolute Champs. Over 5 star customer service.. I'm not kidding’” 🔹“Great service and friendly staff” With spots still available in June, call us today and discover why we're the top choice. Get your free, no-obligation quote now! #AC #HVAC #GrandePrairie #AirConditioning #HVACTechs #HVACExperts #HeatingandCooling #ResidentialButton

-

Start a new career in a growing industry; Pro-West in FORT ST. JOHN 📍 is hiring for REFRIGERATION MECHANIC. Pro-West is continously expanding and we are looking for you to help us grow. We are willing to train the right individual. Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. 🙋🏻♂️We are willing to train the right candidate who has mechanical aptitudes. Experience is an asset but not necessary. The successful candidate must simply possess the drive to learn with the focus of growing into new markets. There is plenty of room for growth, so why not start your future at Pro-West? 💻 Apply via our Careers Page! #WorkforUs #Applytoday #HVAC #HVACTechnicians #HeatingandCooling #ProWest #WesternCanada #Hiring #GrandePrairie #Careers #Edmonton #Vancouver #FortstJohn #Calgary #Headingley #ReginaButton

-

Happy Friday Everyone! Please note our offices will be closed Monday, May 22nd to spend with our families; reopening Tuesday, May 23rd. Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. #ProWest #VictoriaDay #LongWeekend #WesternCanada #HVAC #Langley #GrandePrairie #Winnipeg #Edmonton #Calgary #FortStJohn #Regina #HVACTechnicians #HeatingandCooling #Specialist #MobileACButton

-

Start a new career in a growing industry; Pro-West in Grande Prairie 📌 is hiring for REFRIGERATION TECHNICIAN. Pro-West is continously expanding and we are looking for you to help us grow. Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. There is plenty of room for growth, so why not start your future at Pro-West? 💻 Apply via our Careers Page! #WorkforUs #Applytoday #HVAC #HVACTechnicians #HeatingandCooling #ProWest #WesternCanada #Hiring #GrandePrairie #Careers #Edmonton #Vancouver #FortstJohn #Calgary #Headingley #ReginaButton

-

Start a new career in a growing industry; Pro-West in Grande Prairie 📍 is hiring for HEAVY EQUIPMENT HEATING & REFRIGERATION TECHNICIAN. Pro-West is continously expanding and we are looking for you to help us grow. We are willing to train the right individual. Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📦 We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. 🙋🏻♂️We are willing to train the right candidate who has mechanical aptitudes. Experience is an asset but not necessary. The successful candidate must simply possess the drive to learn with the focus of growing into new markets. There is plenty of room for growth, so why not start your future at Pro-West? 💻 Apply via our Careers Page! #WorkforUs #Applytoday #HVAC #HVACTechnicians #HeatingandCooling #ProWest #WesternCanada #Hiring #GrandePrairie #Careers #Edmonton #Vancouver #FortstJohn #Calgary #Headingley #ReginaButton

-

Morning Work Views 🛻 with Pro-West. #HVAC #HeatingandCooling #WesternCanada #HeavyEquipment #Hitachi #WorkViews #HVACServiceButton

-

Our trucks are ready for you 🛻! Our ability to be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our physical business locations are based in Grande Prairie, Edmonton, Vancouver, Regina, Fort St. John, Winnipeg, and Calgary. Reach out to us today for all your heating and cooling needs! #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanadaButton

-

The heat is HERE ☀️! Keep comfortable and refreshed with Pro-West🙋🏻♂️. Call us today for your free, no obligation quote. ☎️: 1- 780-513-2511 #YorkHomeComfort #AC #Summer #HVAC #HVACTechnician #HeatingandCooling #ProWest #YorkAC #WesternCanada #CallNow #GrandePrairieButton

-

Pro-West on the job; servicing an Engineered Air unit we had installed! Did you know that Pro-West works with a variety of custom units and systems from Engineered Air 🙋🏻♂️? Engineered Air’s ability to design and manufacture each unit to fit the needs and specifications of a project is unparalleled from others. Have more questions about Engineered Air or further information regarding the process of working with us and customizing your future Engineered Air unit? Give us a call today! ☎️:1-866-513-2511 #ProWest #HVAC #HeatingandCooling #EngineeredAir #WesternCanada #HVACTechnicians #CallUs #Blog @engineered_airButton

-

Big or small, we can do it all 🚜! Our ability to be assist you at any one of our branches and be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities🙋🏻♂️. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our branch locations are based in 📍 Grande Prairie 📍 Edmonton 📍 Vancouver 📍 Regina 📍 Fort St. John 📍 Calgary 📍 Winnipeg 🙋🏻♂️Reach out to us today for all your heating and cooling needs! 📸: Featuring our Winnipeg Branch; Heavy Equipment Service. 💻 : https://www.pro-west.ca/ - LINK IN BIO 📦: https://pro-west.shop- LINK IN BIO #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanada #GrandePrairie #Vancouver #FortStJohn #Winnipeg #Regina #Edmonton #CalgaryButton

-

Community Spotlight 💫 We are proud to be a sponsor for the All McG Anchors Hockey Team 🏒! At Pro-West, our commitment to making a positive impact goes beyond our core business operations. We believe in giving back to our community and making a difference in the lives of others. As part of our corporate social responsibility, we actively engage in charity & sponsorship work, striving to make a meaningful contribution to a more compassionate world. #SupportLocal #GrandePrairie #ProudSponsor #Hockey #DiversityButton

-

Spring has Sprung 🌷! Stay Cool with Pro-West 🙋🏻♂️. Call us today for your free, no obligation quote. ☎️: 1- 780-513-2511 #YorkHomeComfort #AC #Summer #HVAC #HVACTechnician #HeatingandCooling #ProWest #YorkAC #WesternCanada #CallNow #GrandePrairie #SpringOfferButton

-

Spring has Sprung 🌷! Stay Cool with Pro-West 🙋🏻♂️. Call us today, for your free no obligation quote. ☎️: 1- 306-737-3405 #YorkHomeComfort #AC #Summer #HVAC #HVACTechnician #HeatingandCooling #ProWest #YorkAC #WesternCanada #CallNow #Regina #SpringOfferButton

-

Wishing everyone a Happy Easter weekend! Please note our office will be closed today- Friday, April 7th to spend with our families; reopening Monday, April 10th. Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. #ProWest #Easter #LongWeekend #WesternCanada #HVAC #HVACTechnicians #HeatingandCoolingButton

-

Our Calgary 📍 location is still looking for Heating & AC Installers! 🙋🏻♂️We are willing to train the right candidate. Mechanical aptitude and experience is an asset but not necessary. There is plenty of room for growth, so why not start your future at Pro-West? 💻 Apply via our Careers Page; Link in Bio! #WorkforUs #Applytoday #HVAC #HVACTechnicians #HeatingandCooling #ProWest #WesternCanada #Hiring #Careers #CalgaryButton

-

Spring is all about new beginnings and transformations. Start a new career in a growing industry; Pro-West is hiring! Pro-West is continously expanding and we are looking for you to help us grow. We are willing to train the right individual. Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📦 We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. 🙋🏻♂️We are willing to train the right candidate who has mechanical aptitudes. Experience is an asset but not necessary. The successful candidate must simply possess the drive to learn with the focus of growing into new markets. There is plenty of room for growth, so why not start your future at Pro-West? 💻 Apply via our Careers Page! #WorkforUs #Applytoday #HVAC #HVACTechnicians #HeatingandCooling #ProWest #WesternCanada #Hiring #GrandePrairie #Careers #Edmonton #Vancouver #FortstJohn #Calgary #Headingley #ReginaButton

-

Spring is all about new beginnings and transformations. Start a new career in a growing industry; Pro-West is hiring! Pro-West is continously expanding and we are looking for you to help us grow. We are willing to train the right individual. Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📦 We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. 🙋🏻♂️We are willing to train the right candidate who has mechanical aptitudes. Experience is an asset but not necessary. The successful candidate must simply possess the drive to learn with the focus of growing into new markets. There is plenty of room for growth, so why not start your future at Pro-West? 💻 Apply via our Careers Page! #WorkforUs #Applytoday #HVAC #HVACTechnicians #HeatingandCooling #ProWest #WesternCanada #Hiring #GrandePrairie #Careers #Edmonton #Vancouver #FortstJohn #Calgary #Headingley #ReginaButton

-

As the online store for Pro-West Refrigeration Ltd and Eberspaecher’s Largest Master Service Distributor, Pro-West.Shop is backed by industry leading inventory and the best pricing of popular Eberspächer / Espar and Kalori products. We've made shopping online a breeze, so that your equipment can spend more time working and you can spend less time searching through catalogs! 🔗 in Bio to shop now! #Eberspaecher #Espar #Eberspächer #Kalori #HVAC #ProWest #Eberspacher #HeatingandCooling #HVACTechnicians #ProWestShop #BuyNow #heaters #parts #accessories #SaveMoneyBuyOnlineButton

-

We’re happy to be part of the Manitoba Trucking Association, working together to serve the industry that drives the nation. #MBtrucking #CanadaMovesByTruck #ProWest #Manitoba #HeavyEquipment #HeatingandCooling #HVACTechnicians #HVACButton

-

Pro-West on the job🙋🏻♂️! Our ability to be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our physical business locations are based in Grande Prairie, Edmonton, Vancouver, Regina, Fort St. John, Winnipeg & Calgary. Reach out to us today for all your heating and cooling needs! #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanadaButton

-

✨Client Testimonial✨ We always love to hear our Clients’ experiences with our team and the services we offer. Pro-West Refrigeration Ltd. proudly works to ensure all inquiries are fulfilled exceeding expectations in a timely manner, while demonstrating excellent workmanship. In addition to our on-site and mobile services across Western Canada, did you know we have an online shop 📦: Pro-West Shop, where you can purchase an array of parts and products? As the online store for Pro-West Refrigeration Ltd: Eberspaecher’s Largest Master Service Distributor, Pro-West.Shop is backed by industry leading inventory and the best pricing of popular Eberspächer / Espar and Kalori products. Had a recent Pro-West service from us? Please share your experiences with us via Google Review; we always love to hear from you ✍️ ! #ProWest #ProWestShop #ClientTestimonials #WesternCanada #GoogleReviews #SaveMoneyBuyOnline #HVAC #ProWest #HeatingandCooling #HVACTechnicians #ProWestShop #InstallServices #accessories #Espar #EberspacherButton

-

Happy Family Day! Please note our offices will be closed today, February 20th, to spend some much needed time with our loved ones. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. #ProWest #ProWestShop #HVACButton

-

☀️ Beat the Heat with our AC Pre-Summer Offer 📣! Call us today for your free no obligation quote. ☎️: 1- 780-513-2511 #YorkHomeComfort #AC #Summer #HVAC #HVACTechnician #HeatingandCooling #ProWest #YorkAC #WesternCanada #CallNow #GrandePrairie #SummerOfferButton

-

☀️ Beat the Heat with our AC Pre-Summer Offer 📣! Call us today for your free no obligation quote. ☎️: 1- 306-737-3405 #YorkHomeComfort #AC #Summer #HVAC #HVACTechnician #HeatingandCooling #ProWest #YorkAC #WesternCanada #CallNow #Regina #SummerOfferButton

-

Our ability to be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our physical business locations are based in Grande Prairie, Edmonton, Vancouver, Regina, Fort St. John, Winnipeg & Calgary. Reach out to us today for all your heating and cooling needs! 📸 📍 Winnipeg Branch #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanada#WinnipegButton

-

Pro-West on the job replacing old, mid efficient furnaces with new, high efficient YORK furnaces 🙋🏻♂️! Reach out to us today for all your heating and cooling needs! #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanada #GrandePrairie #YorkHomeComfortButton

-

Did you know about our newest branch in the Manitoba area?! 📍 500 Caron Road Headingley, Manitoba R4H 1B4 ☎️: 1-(204) 333-6146 📧: Ingvarj@pro-west.ca Our ability to be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our physical business locations are based in Grande Prairie, Edmonton, Vancouver, Regina, Fort St. John, Winnipeg & Calgary. Reach out to us today for all your heating and cooling needs! #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanada#WinnipegButton

-

Pro-West on the job, working on a Bron Mulcher 🚜! Our ability to be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our physical business locations are based in Grande Prairie, Edmonton, Vancouver, Regina, Fort St. John, Winnipeg & Calgary. Reach out to us today for all your heating and cooling needs! #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanada #BronMulcher #Edmonton @rwfbron #heavyequipmentButton

-

Massive Overstock Clearance 📣!!! 🔹Furnace Replacements starting at $3,495 🔹Free Estimates 🔹Financing Options Available 📞 Call Today: 306-737-3405 🔗 in Bio to our Website #ProWest #HVAC #YorkAC #WesternCanada #Residential #Commercial #HeatingandCooling #HVACTechnicians #theExperts #Furnaces #Install #CallToday #YorkHomeComfort #FurnaceReplacement #FurnaceButton

-

Massive Overstock Clearance 📣!!! 🔹Furnace Replacements starting at $3,495 🔹Free Estimates 🔹Financing Options Available 📞 Call Today: 780-513-2511 🔗 in Bio to our Website #ProWest #HVAC #YorkAC #WesternCanada #Residential #Commercial #HeatingandCooling #HVACTechnicians #theExperts #Furnaces #Install #CallToday #YorkHomeComfort #Furnace #FurnaceReplacementButton

-

Pro-West on the job with Edmonton Transit on some active air installs 🚌 🙋🏻♂️! Our ability to be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our physical business locations are based in Grande Prairie, Edmonton, Vancouver, Regina, Fort St. John, Winnipeg & Calgary. Reach out to us today for all your heating and cooling needs! #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #Edmonton #HeatingandCooling #HeavyEquipment #WesternCanadaButton

-

Starting 2023 off with these amazing work views 🌅. Pro-West on the job🙋🏻♂️! Our ability to be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our physical business locations are based in Grande Prairie, Edmonton, Vancouver, Regina, Fort St. John, Winnipeg & Calgary. Reach out to us today for all your heating and cooling needs! #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanadaButton

-

Best wishes for the Holidays, and for health and happiness throughout the coming year! Please note our offices will be closed January 2nd to spend some time with our loved ones. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. Happy Holidays ❄️! #ProWest #ProWestShop #HolidayHours #HVACButton

-

On behalf of the Pro-West team, Merry Christmas! Please note our offices will be closed December 26th and 27th respectively to spend some much needed time with our loved ones🎄. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. Happy Holidays ❄️! #ProWest #ProWestShop #HolidayHours #HVACButton

-

With Canada under more than 400 weather warnings and winter storms, now is the time to make sure you’re prepared! Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📦We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. Reach out to us today and stay warm with Pro-West! ☎️ 1-866-513-2511 #Eberspaecher #Espar #Eberspächer #Kalori #HVAC #ProWest #HeatingandCooling #HVACTechnicians #ProWestShop #BuyNow #heaters #parts #accessories #SaveMoneyBuyOnline #Trucks #WinterButton

-

Please note our office holiday hours above for when we will be closed to spend some much needed time with our families 🎄. ✨Should you require any assistance outside our office hours, one of our team members can be reached at 📞: 1-866-513-2511. Happy Holidays Everyone! #ProWest #ProWestShop #HolidayHours #HVAC #OnCallButton

-

🥶 Extreme Cold Warnings continue to blanket Western Canada! The cold is expected to continue through this week. Let Pro-West keep you, your family, your vehicle, and your place of business, warm! 🙋🏻♂️Pro-West specializes in the heating, cooling, installation, repair, and maintenance of residential, commercial, heavy equipment, and refrigeration systems. 📦 We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. Whether you need to warm up your Truck 🛻 , your work place 🏗️, or ensure your home🏠 is fully equipped to keep you and your family nice and cozy this festive holiday season, reach out to Pro-West for all your heating needs! 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. Call today! ☎️ 1-866-513-2511 #Eberspaecher #Espar #Eberspächer #Kalori #HVAC #ProWest #HeatingandCooling #HVACTechnicians #ProWestShop #BuyNow #heaters #parts #accessories #Residential #Commercial #Parts #HeavyEquipment #SaveMoneyBuyOnline #Trucks #WinterButton

-

MAKE THE MOVE with PRO-WEST! #WeAreHiring 📣 We’re offering opportunities that include: 🔹Wage- $50-$55* 🔹Overtime Wage 🔹Boot Allowance 🔹Tools Allowance 🔹Comprehensive Benefits Package 🔹Relocation costs** 🙋🏻♂️Pro-West specializes in the heating, cooling, installation, repair, and maintenance of residential, commercial, heavy equipment, and refrigeration systems. 📦 We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. 🔍We are looking for friendly, dedicated, and motivated people with the technical aptitude, initiative, and passion for excellence, to join our Company and help us grow. 📍Grande Prairie, where our flagship branch is located, is a youthful, family friendly, fast-growing community. Home to a skilled workforce, a diversified economy, and proudly holding the status as the Most Entrepreneurial Community in Canada for three consecutive years. 🏡 With its affordable real estate coupled with high average household incomes compared to the national average, Grande Prairie residents are accustomed to a comfortable lifestyle. 🙋🏻♂️Come work for the Heating and Cooling specialists in Western Canada; for a progressive company with numerous opportunities for performance and advancement. 💻Have experience in the field and looking for a fresh start? Apply today, make the move, and start your future at Pro-West! 📧 Submit your application to safety@pro-west.ca _________________________ 🔗 www.pro-west.ca ✨NB:✨ *Based on Experience **Must work a minimum duration of time to be eligible #MakeTheMove #WorkWithUs #GrandePrairie #Applytoday #Careers #Opportunities #YQU #ProWest #HeatingandCooling #HVAC #GPTourismButton

-

🥶 Extreme Cold Warning! A notification in effect you’re probably seeing pop up on your phones this week. Let Pro-West keep you warm! 🙋🏻♂️Pro-West specializes in the heating, cooling, installation, repair, and maintenance of residential, commercial, heavy equipment, and refrigeration systems. 📦 We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. Whether you need to warm up your Truck 🛻 , your work place 🏗️, or ensure your home🏠 is fully equipped to keep you and your family nice and cozy this festive holiday season, reach out to Pro-West for all your heating needs! 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. Call today! ☎️ 1-866-513-2511 #Eberspaecher #Espar #Eberspächer #Kalori #HVAC #ProWest #HeatingandCooling #HVACTechnicians #ProWestShop #BuyNow #heaters #parts #accessories #Residential #Commercial #Parts #HeavyEquipment #SaveMoneyBuyOnline #Trucks #WinterButton

-

From the everyday to special moments; whether you’re at work or with your loved ones, let Pro-West keep you warm this festive 🎄 season! 🙋🏻♂️Pro-West specializes in the heating, cooling, installation, repair, and maintenance of residential, commercial, heavy equipment, and refrigeration systems. 📍 With branches across Western Canada, we offer onsite and mobile services. ☎️ Call us today: 1-866-513-2511 #HVAC #ProWest #HeatingandCooling #CallToday #GrandePrairie #Langley #Calgary #FortStJohn #Edmonton #Winnipeg #Regina #HVACTechniciansButton

-

MAKE THE MOVE with PRO-WEST! #We’reHiring 📣 We’re offering opportunities that include: 🔹Wage- $50-$55* 🔹Overtime Wage 🔹Boot Allowance 🔹Tools Allowance 🔹Comprehensive Benefits Package 🔹Relocation costs** 🙋🏻♂️Pro-West specializes in the heating, cooling, installation, repair, and maintenance of residential, commercial, heavy equipment, and refrigeration systems. 📦 We are Western Canada’s largest supplier of Eberspaecher/Espar and Bergstrom products. 🔍We are looking for friendly, dedicated, and motivated people with the technical aptitude, initiative, and passion for excellence, to join our Company and help us grow. 📍Grande Prairie, where our flagship branch is located, is a youthful, family friendly, fast-growing community. Home to a skilled workforce, a diversified economy, and proudly holding the status as the Most Entrepreneurial Community in Canada for three consecutive years. 🏡 With its affordable real estate coupled with high average household incomes compared to the national average, Grande Prairie residents are accustomed to a comfortable lifestyle. 🙋🏻♂️Come work for the Heating and Cooling specialists in Western Canada; for a progressive company with numerous opportunities for performance and advancement. 💻Have experience in the field and looking for a fresh start? Apply today, make the move, and start your future at Pro-West! 📧 Submit your application to safety@pro-west.ca __________________ 🔗 www.pro-west.ca ✨NB:✨ *Based on Experience **Must work a minimum duration of time to be eligible #MakeTheMove #WorkWithUs #GrandePrairie #Applytoday #Careers #Opportunities #YQU #ProWest #HeatingandCooling #HVAC #GPTourismButton

-

Is this your current work view these days 🥶? Let Pro-West make your Vehicle as warm and cozy as your home! Pro-West specializes in the installation, repair, and maintenance of residential, commercial, and heavy equipment; heating, cooling, and refrigeration systems. 📦We are Western Canada's largest supplier of Eberspaecher/Espar and Bergstrom products. 📍 We currently have branches in Fort St. John BC, Langley BC, Calgary AB, Edmonton AB, Regina SK, Winnipeg MB, and our head office in Grande Prairie AB. Reach out to us today and stay warm with Pro-West! ☎️ 1-866-513-2511 #Eberspaecher #Espar #Eberspächer #Kalori #HVAC #ProWest #HeatingandCooling #HVACTechnicians #ProWestShop #BuyNow #heaters #parts #accessories #SaveMoneyBuyOnline #Trucks #WinterButton

-

✨Client Testimonial✨ We always love to hear our Clients’ experiences with our team and the services we offer. Pro-West Refrigeration Ltd. proudly works to ensure all inquiries are fulfilled exceeding expectations in a timely manner, while demonstrating excellent workmanship. In addition to our on-site and mobile services across Western Canada, order and array or parts and products from us via 📦 Pro-West Shop online! As the online store for Pro-West Refrigeration Ltd: Eberspaecher’s Largest Master Service Distributor, Pro-West.Shop is backed by industry leading inventory and the best pricing of popular Eberspächer / Espar and Kalori products. Reach out to us for all your heating and cooling needs! #ProWest #ProWestShop #ClientTestimonials #WesternCanada #GoogleReviews #SaveMoneyBuyOnline #HVAC #ProWest #HeatingandCooling #HVACTechnicians #ProWestShop #InstallServices #accessories #Espar #EberspacherButton

-

📍 Did you know we have several branches across Western Canada? Our ability to be assist you at any one of our branches and be mobile where we can come to you, 24 hours a day, across several locations in Western Canada is what distinguishes our services and capabilities. Our fantastic team are certified Red Seal Journeyman HVAC/R Mechanics with all the updated and required health & safety certifications. Their comprehensive knowledge, years of experience, and excellent workmanship is unparalleled. Our branch locations are based in: 📍 Grande Prairie 📍 Edmonton 📍 Vancouver 📍 Regina 📍 Fort St. John 📍 Calgary 📍 Winnipeg ✨Coming Soon!✨ 🙋🏻♂️Reach out to us today for all your heating and cooling needs! 💻 : https://www.pro-west.ca/ 📦: https://pro-west.shop #ProWest #Commercial #Residential #HeavyDuty #ProWestShop #MobileServices #ProWestontheJob #HVAC #HVACTechnicians #HeatingandCooling #HeavyEquipment #WesternCanada #GrandePrairie #Vancouver #FortStJohn #Winnipeg #Regina #Edmonton #CalgaryButton

-